Working with a cube and cylinder

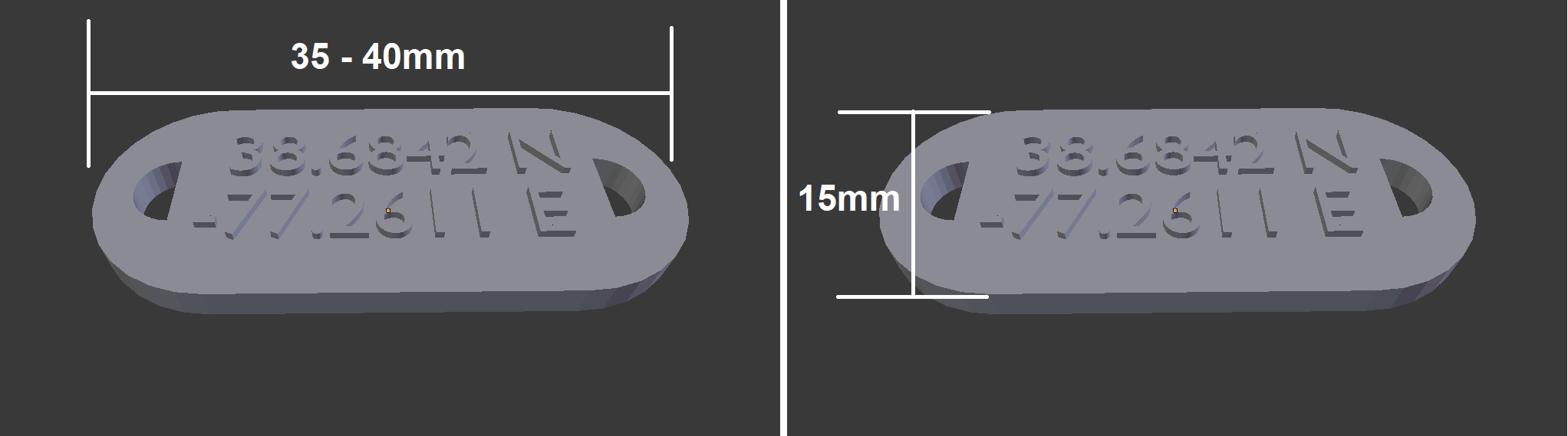

Before we begin, let's reflect on the concepts from Chapter 1, Thinking about Design Requirements, and think about the sizing of our plate. Using my own wrist as a guide, I determine how long and wide I want it:

Brainstorming dimensions of the final piece

For the height (thickness) of the piece, the printing process is going to be the determining factor. The sizing I end up with is as follows:

Dimension | Service Bureau(Shapeways Strong and Flexible Plastic) | At Home(FFF/FDM) |

Length | 35-40mm | 35-40mm |

Width | 15mm | 15mm |

Height | 1mm (Slightly bigger than the minimum wall thickness of 0.7mm) | 2mm |

Resizing the default cube

For this project, the default cube can contribute to our final model. Instead of deleting it, like we did in Chapter 2, Using a Background Image and Bezier Curves, we can resize it to our needs. We are going to use the Mirror Modifier later in this chapter, so we will only be modeling half of the base. Since the eventual curved edges will add to the total length, I...