Reviewing our print results

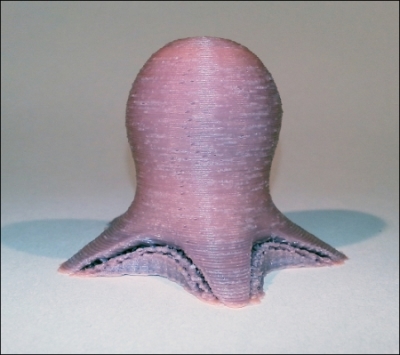

Generating good support material is a balancing act between fabricating enough layers that will prevent the drooping of the filament and creating layers that are weak enough that they can be removed. In the following image, we can see the support structure under the model of the jellyfish form:

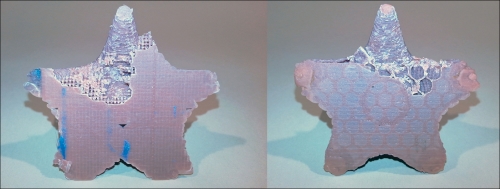

In the following image, we can see the partial removal of support that was generated with the default values in Skeinforge on the left-hand side and Slic3r on the right-hand side:

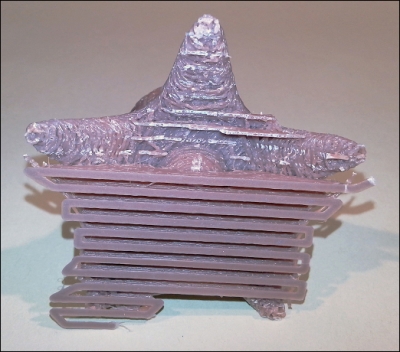

Both of these slicers produced a support that was difficult to remove. By changing the pattern's shape to rectangular and increasing the pattern spacing, both slicers generated a support that was easier to remove. This can be seen in the following two images:

In the preceding image, Skeinforge generated a support that was removed in one piece.

In the preceding image, Slic3r generated a support that was easily removed with a pair of pliers.

A fine finish typically cannot be achieved in areas where support...