Kaizen – Continuous Improvement

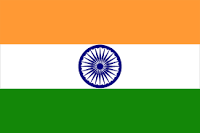

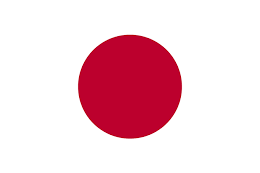

In the 1950's, Toyota Motor Corporation began a company-wide endeavor to develop and deliver automotive solutions that could compete against the well-entrenched American auto manufacturers of that era. Upon embarking on this journey, Toyota (the only Japanese auto manufacturer) lacked the manufacturing efficiency required to adequately expand its business to a global audience. To address these deficiencies, Toyota innovated Kaizen culture, and implemented Continuous Improvement initiatives across the organization. This began Toyota's long journey to improve quality and assembly-line throughput at its production plants. These initiatives would eventually vault Toyota into global success.

"Kaizen is the belief that many small changes over time create huge changes in the future." | ||

| --Toyota.com | ||

The word Kaizen can be directly translated as, to change for the better. Kai is most commonly translated into English as change, and Zen translates as good. The English...